Benefits of technology

- Durability and a wide range of textures

- Painting forms an impact-resistant anti-corrosion coating that can withstand a temperature range from -60 to + 150C and ensures stability, strength and durability.

- The choice of colours and textures is practically unlimited. It is possible to choose any shades and textures: gold or silver metallic, imitation of bronze, copper, stone, etc.

- Cost effective

- Paints are supplied ready-made, which eliminates expensive viscosity control and tinting procedures.

- No solvents – saving on paint costs.

- Low waste. Almost 100% of the paint is transferred to the work surface

- About 95% of the paint collected in the process can be reused

Environmental friendliness- No flammable or toxic liquid solvents are used

- No harmful organic compounds

- No chemical smell

- Fire safety

Features of the technology

Powder painting of metal products in our company is performed in three stages:

- Surface preparation. Stubborn stains, rust, scale or paint can be removed using shot blasting and laser cleaning. Degreasing, phosphating and application of zinc-containing primer are carried out to protect the product from corrosion.

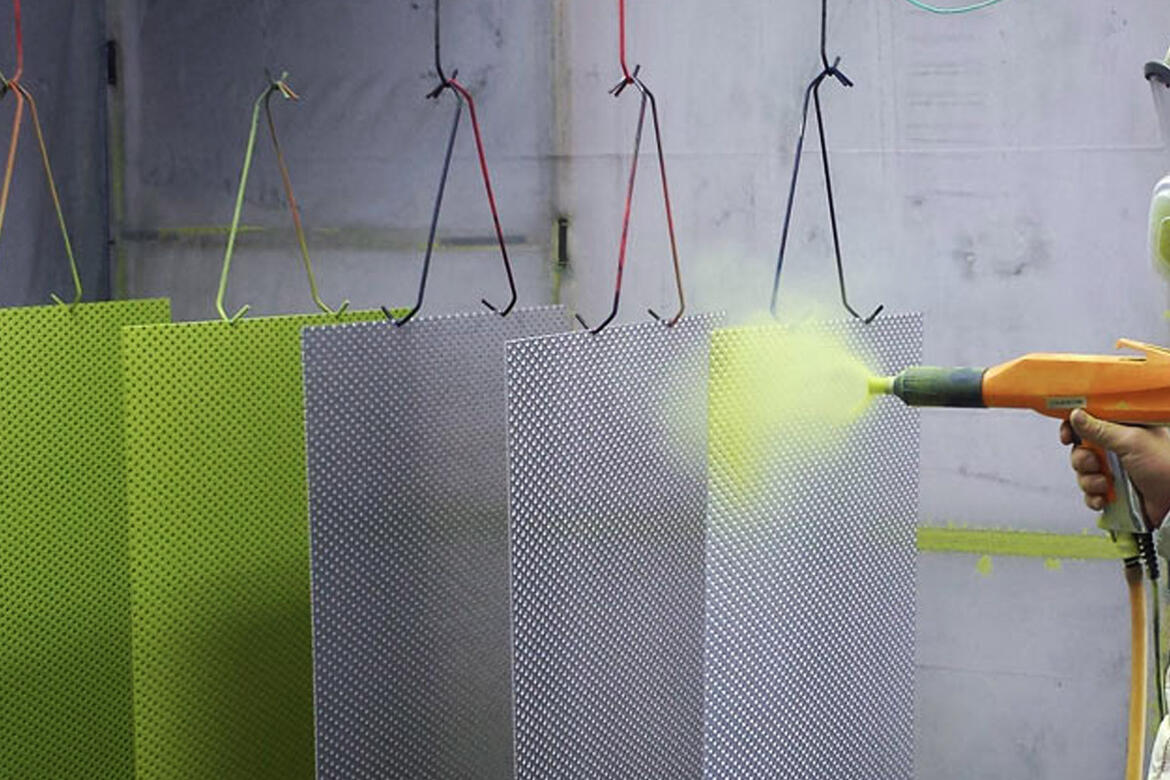

- Paint application. The parts are placed in the paint booth. The paint is sprayed under the influence of an electrostatic field - the powder evenly covers the parts and penetrates into hard-to-reach places.

- Polymerization. The products are moved into 3000x2100x1200 polymerization oven and kept at temperatures from 140 to 220°C. Baking time – 15-30 minutes.

Advantages over solvent paints

- Excellent decorative, physical, chemical and performance properties

- No surface primer required

- Single coat application, as opposed to multi-layer liquid coatings

- Low porosity, excellent anti-corrosion properties

- No tinting or viscosity control required

- Material loss is only 1-5% (about 40% when painting with liquid paints)

- Coating cures within 30 minutes

- Damage to products to be painted during transportation and packaging costs are kept to a minimum.

Limitation of technology

- Painting is possible only in production conditions using special equipment

- Colouring is not possible; only ready-made paints from the manufacturer are used.

- Local defects are difficult to eliminate; usually you have to repaint the product completely

- Only products made of heat-resistant materials can be painted (polymerization temperature 140-220°C);

- The dimensions of the painted products are limited by the overall dimensions of the polymerization oven 3000x2100x1200.