Metalworking according to drawings - manufacturing products according to individual customer requirements (required design and specific dimensions). Often such a service is needed if it is not possible to find the desired product in finished form. Another reason to make custom-made hardware: there is a need to create a unique part according to your own drawing. Sometimes there is even a need to make something in a single copy. Sometimes, on the contrary, a manufacturer is looking for a subcontractor to produce a whole series of the same type of non-standard hardware necessary for inclusion in the design of its own products.

Non-standard hardware are products that are made to order according to an individual project.

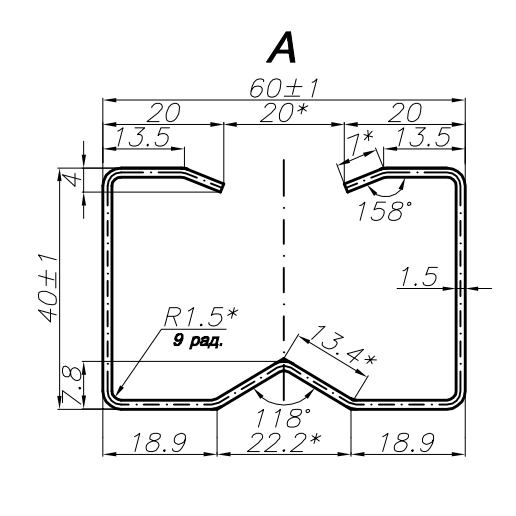

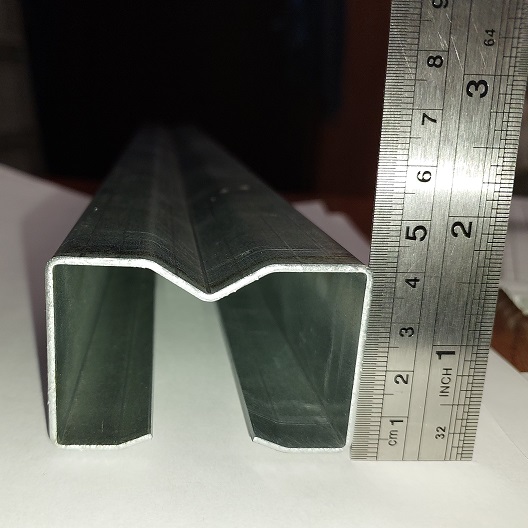

Non-standard metal structures are also often needed in a single copy or in a limited series, and they are performed according to an individual project, layout, or sketch. High-precision bending, cutting, perforation of sheet metal on Trumph machines allows our company to make the project being implemented not only truly exclusive, but also to carry it out in full compliance with the requirements set out in the technical documentation, observing impeccable (if mass production is necessary) repeatability of products.

If necessary, we finalize technical tasks, design sketches of hardware, and create design documentation.

We use advanced equipment to produce parts with exceptional precision. Laser cutting up to 8 mm, precision bending up to 3000 mm long, stamping, die-cutting, powder painting, cutting rolled metal up to 1.2 mm.