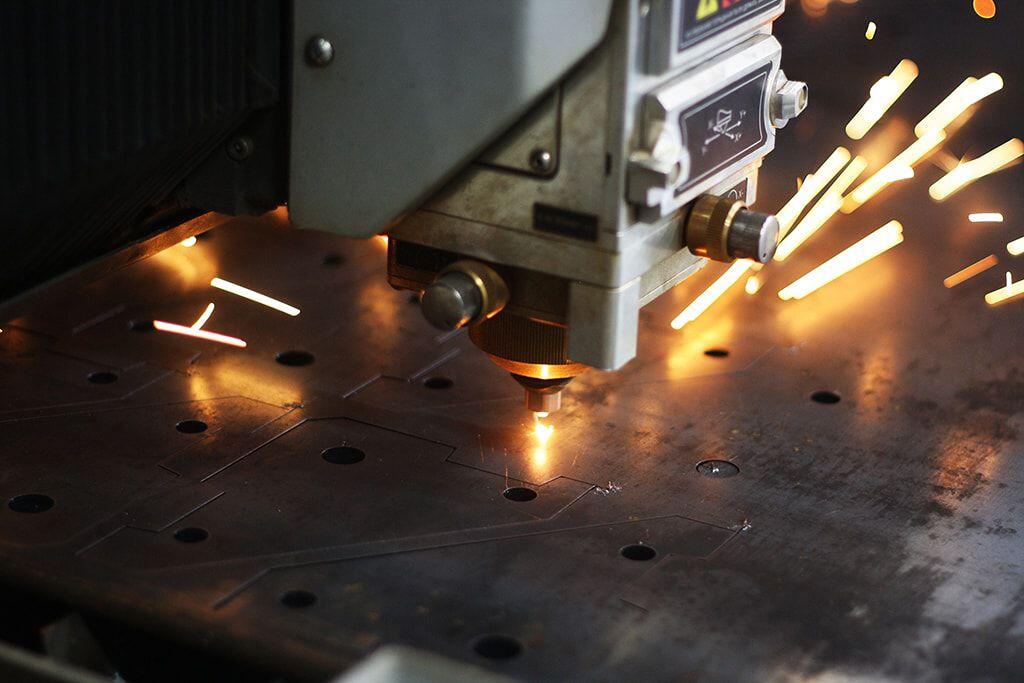

An almost perfectly smooth cut edge is formed, which does not require additional processing and has no traces of geometric defects. The resulting parts are completely suitable for further production operations of the final product.

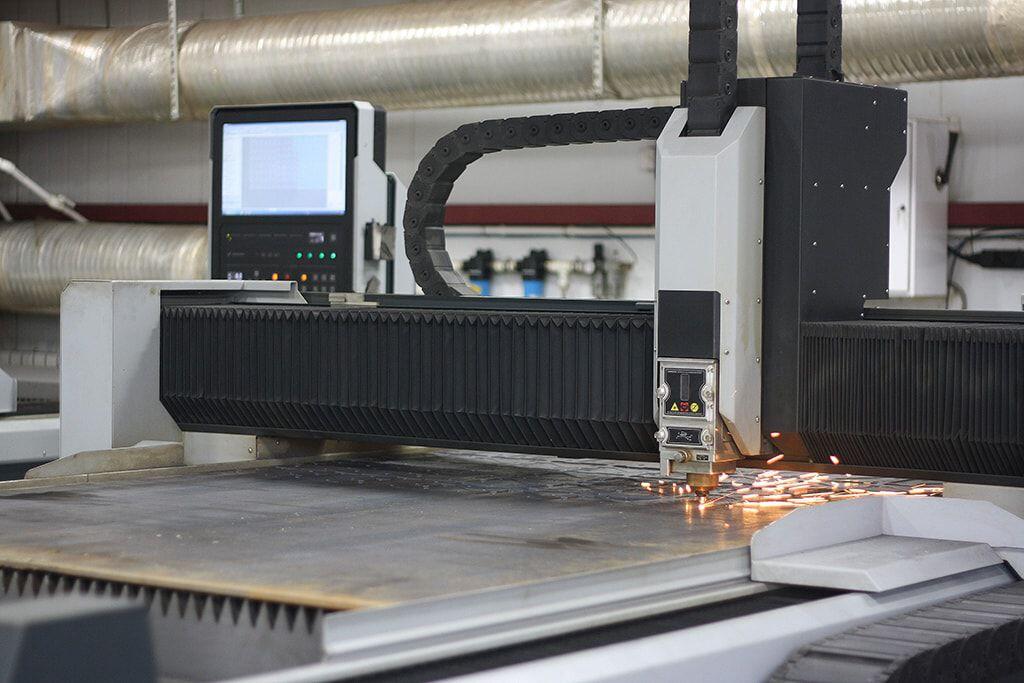

In order to achieve the necessary results when laser processing of metal, it is necessary to carefully select cutting equipment, processing parameters, as well as the process gas with which the metal will be cut.

Dozens of settings for the cutting complex have a direct impact on the parts quality and speed of manufacturing.

It is necessary to take into account the operational characteristics and capabilities of the equipment used, the overall dimensions of the part being manufactured, the requirements for geometric accuracy and cut quality, the type of alloy being processed and the thickness of the part being processed.

It is important to understand that laser cutting of metal is usually only the first step in the manufacturing process of the final product. Therefore, it is necessary to take into account what process operations the processed part will undergo at subsequent stages of production.

As for the speed that laser cutting of metal can provide, it is ultimately influenced by the thickness of the workpiece and the type of alloy, the level of thermal conductivity and the degree of reflection of the metal, the power and technical capabilities of the laser equipment used, etc.